Like the old refrain goes, “there are only two kinds of concrete: cracked concrete and concrete that will crack.” Engineers and builders do their utmost to limit and control cracking to preserve structural integrity and aesthetics by employing various methods. We create control joints, construction joints, expansion joints, provide temperature and shrinkage reinforcing using welded wire fabric, fibers and rebar. In synopsis, we go thru a lot of effort to mitigate cracking concrete. So then, why would a builder ever expressly create a condition where concrete is likely to crack and compromise structural integrity? This cementitious sin is more common than you might think, and the guilty party is often an expansion anchor installed in a close edge condition.

Expansion anchors inherently work by, you guessed it, expanding! When installed, the expansion anchor is hammered into a predrilled hole in the concrete. Then a wedge at the base of the anchor is drawn up thru a sleeve which expands against the drilled hole within concrete. Naturally, this expansive force creates stresses within the concrete that must be resisted. While concrete is a natural champ in compression, it is an abysmal wimp in tension. So when these stresses need to be resolved near a slab edge, resultant forces can create splitting within the concrete that will likely propagate cracks extending out from the anchor. These cracks can compromise the integrity of the connection and aesthetically ruin your slab edges.

However, there is a time and place for expansion anchors though. They are widely available and an economic solution for anchoring within interior slab conditions or when set within minimum edge distances on foundations. Specific anchors can vary based on the manufacturer, but for a typical 5/8” diameter anchor to achieve full capacity, the minimum edge spacing is usually 10”. Some anchor manufacturers allow lesser minimum edge distances, down to 4-1/2”, but with significant reductions in capacity. In the absence of manufacturer recommendations tested per ACI 355, the minimum edge distance of expansion anchors (displacement or torque controlled) must be checked for side-face blowout failure and cannot be less than 8 anchor diameters per ACI 318-11 appendix D8.3 and ACI 318-14 section 17.7.3.

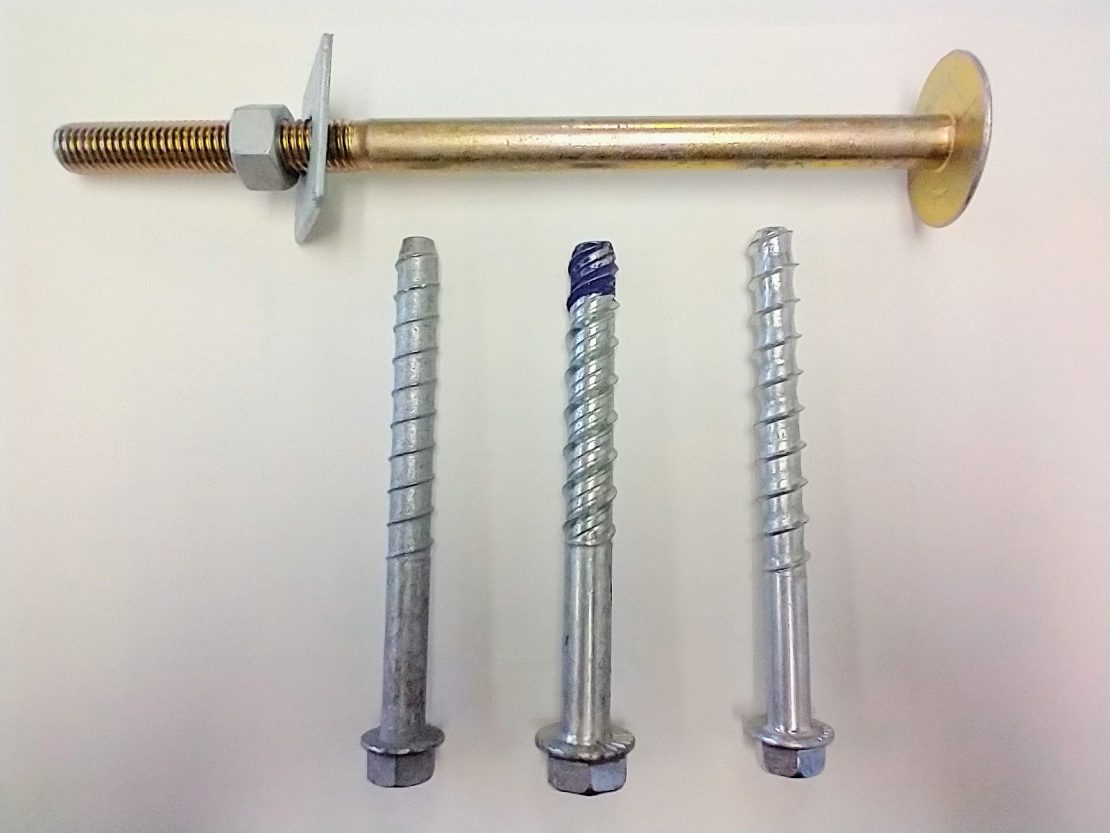

Architects, engineers, contractors, and do-it-yourselfers may be asking themselves right now, “Ay bendito! How can I attach a sill plate at an exterior wall to my slab without wedge anchors!?!” The limitations of expansion anchors (wedge and sleeve anchors) noted above preclude their use in exterior wall applications near slab edges. Well, despair not, you can always specify a cast-in-place anchor like the TIEMAX Edge Bolt which has higher holding power and is specifically designed for close edge conditions as little as 2”. Also, if you need is a post-installed solution, then there is always the drill and epoxy TIEMAX Stud or the Large Diameter Tapcon that comes in many sizes and flavors. These are all available from Fastening Specialists Inc:

Author: Enrique Fernández, PE